How can distributors maintain a lean supply chain when marketplace turbulence compels them to buffer for hard times ahead?

Before the pandemic, accurate forecasting and demand planning made supply chain management somewhat predictable. Distributors within a lean supply chain were able to deliver more customer value with diversified product inventory while reducing operating expenses.

Since the pandemic, marketplace volatility and shutdown-related disruptions have thrown a monkey wrench at supply chains across the world. When supply chains failed to keep pace with demand, partners across the chain began to purchase more inventory at hiked-up rates as a buffer against uncertainty, driving prices up for end customers, who in turn bought less. With demand for products plunging, distributors were left with excess inventory that they had purchased at a premium.

This vicious cycle has not completely abated. Prices remain volatile and costs continue to change frequently. But distributors who persist in implementing lean supply chain strategies will leapfrog their peers in delivering more customer value while realizing more profit. Improvements in their financial performance will be the indicator that lean supply chain is their best hedge against more economic uncertainty ahead.

This article will address what lean supply chain management looks like and how to adopt it.

What is Lean Supply Chain Management?

Lean supply chain management is defined as the integration and management of organizations both upstream and downstream to deliver goods or products to customers when they want it while reducing cost and waste. For distributors, keeping a lean supply chain means having enough inventory to satisfy “A orders.” Those distributors who are able to satisfy every single order likely have too much inventory on-hand. While delivering products to the customer on-time certainly fosters loyalty, distributors must strike a balance between customer satisfaction and company profitability. The goal of course is to deliver an entire order when the customer wants it– the “perfect order.” And, distributors who keep customers apprised of their orders will develop and maintain a reputation for reliability and transparency, which in turn helps discourage customers from padding their requirements and deadlines, which can set off buffering behavior up the chain and trigger price hikes.

Lean supply chain management is simple in theory, but can be difficult in application. Supply chains can often be affected by pricing instability. Distributors must be able to react to changes in lead times and usage when market conditions are disrupted. The costs of retaining each item must be compared to the costs of losing a potential sale. Not all items are created equal – customer stratification and inventory management techniques must be used to rank items by hits. Distributors must then deploy allocation methods that accurately reflect the customer’s value to the organization in order to keep supply chains lean. Lean supply chains are all about delivering products to customers efficiently while still continuing to be profitable.

How Can Distributors Adopt this Methodology?

Adopting lean supply chain management requires making a commitment to monitoring and measuring business performance against expected outcomes to ensure excess inventory is minimized, or even eliminated. Those outcomes will vary and will depend on the industries your customers belong to. For instance, the best practices for distributors within the medical industry, where it’s not unusual to carry surplus knowing customers will eventually purchase the goods at prices higher than cost, will differ from those for distributors within plumbing, where there’s no such certainty.

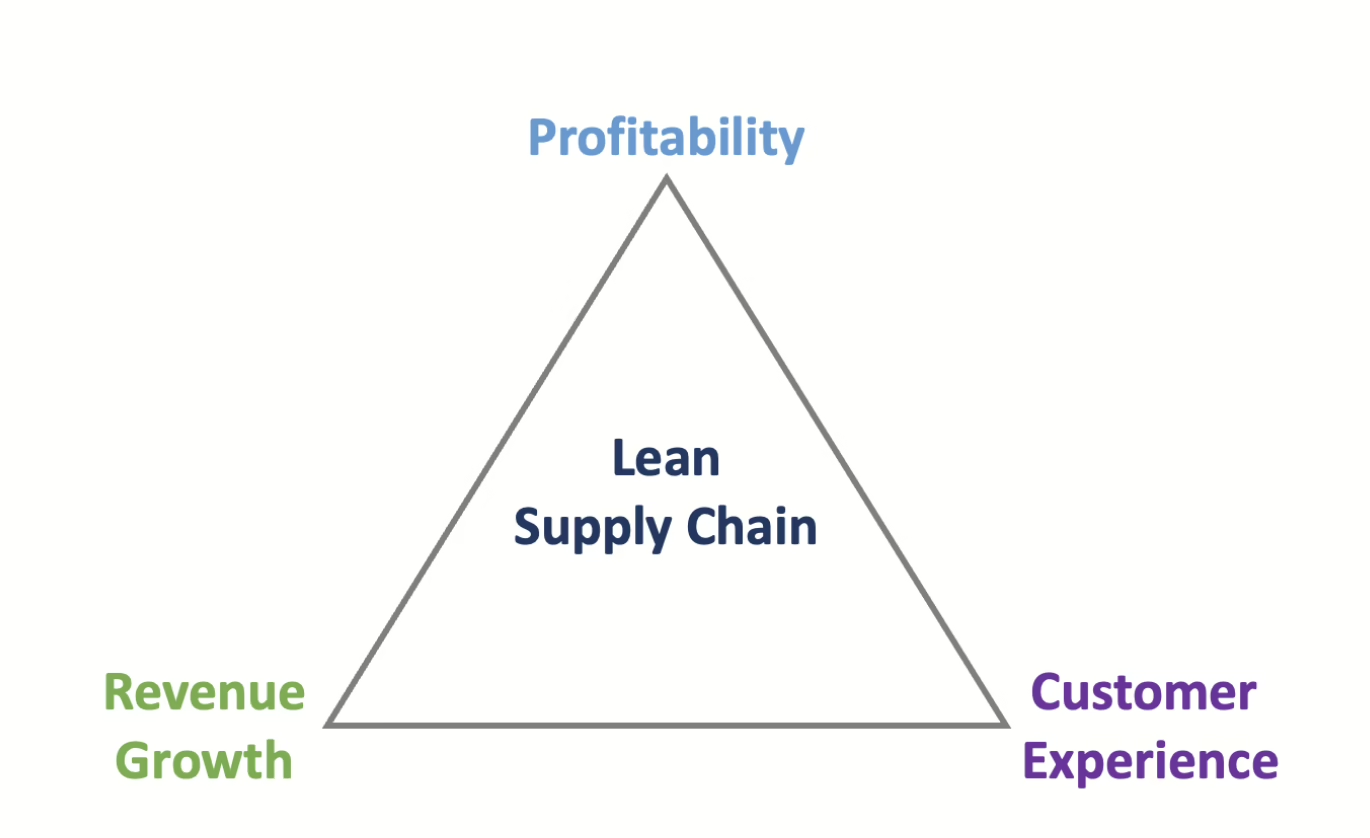

However, top executives of any distributor, no matter the size of the business or who the business serves, need to pay attention to these important, interrelated performance indicators: profitability, customer experience, and growth. We call this the “lean supply chain triangle”. Balancing these three indicators will help any distributor maintain a lean supply chain and increase their likelihood of success no matter the market conditions.

Profitability

Distributors in pre-COVID times could focus on growing market share, even at the expense of profitability in a market where forecasting the availability of goods and lead times were simpler. Today’s unpredictable, volatile marketplace has turned forecasting on its head. In order to succeed in such an environment, distributors must maintain sufficient liquidity, growing both top line revenue and net income simultaneously.

Gross margins alone won’t paint a full picture of profitability. Distributors need to take a harder look at inventory value and inventory turns, the number of times inventory is sold over a predetermined period, to understand how well–or poorly–they use these assets in generating earnings. They must be able to manage short-term and long-term surpluses while considering product lead times. Knowing your inventory and improving your demand forecast’s accuracy can help you make informed decisions on problems and opportunities down the road.

Monitoring inventory allows for better purchasing decisions to be made, in turn resulting in increased sales and improved customer satisfaction. Sales teams, management, and executives should be kept abreast of that state of inventory. If turnover is too low, sales and marketing efforts should be reviewed and adjusted accordingly.

Customer Experience

Keeping customers happy is the first priority of any business. For distributors, this means delivering the right goods at the right time, also known as the perfect order. Indicators of customer experience include what percentage of goods were filled, what percentage were shipped on time, and what percentage were shipped accurately.

The path to delivering the perfect order is paved with effective, timely communications. Supply chain management would be impossible without it. Distributors need to communicate frequently with the wholesalers and retailers they serve for three key reasons: first, to understand customers’ priorities and challenges; second, to uncover and help solve other issues they might not even be aware of; third, to avoid any unwanted surprises. All three will help you earn customers’ trust and more of their business to help you grow yours.

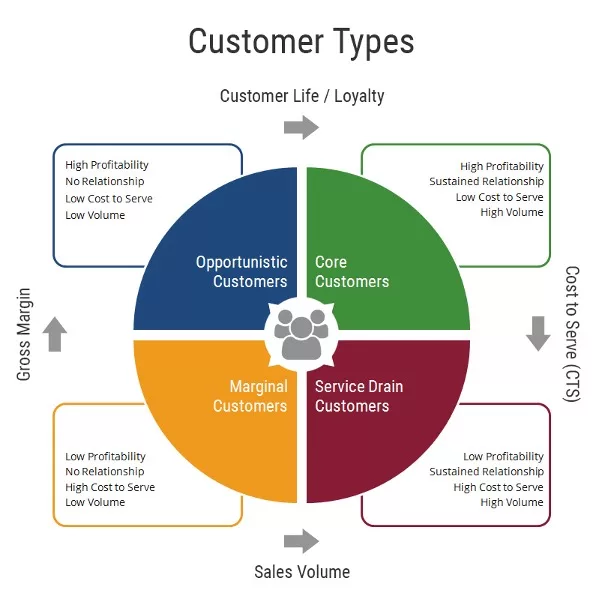

But, you can’t deliver the perfect order to all customers. If you could, you probably carry more inventory than you should. You need to stratify your customers first, then decide who your core customers are. These customers are characterized by the alignment of their needs with your offerings, high profitability and high volume, an enduring relationship, and service levels that don’t eat into your margins. You can turn opportunistic customers into core customers by building new or stronger relationships through better or more relevant service. Moving service drain customers to the core customers box will require taking a hard look at customer behaviors driving up the cost to service them to make informed decisions on how to change those behaviors. It might also mean working closely with suppliers on modifying those behaviors.

Growth

Your revenue strategy will need to consider the other two points of the triangle: profitability and customer longevity. After all, you can’t be successful if the returns on inventory and on your customer base are poor. Achieving revenue growth will rest on growth in most, if not all, of the following variables:

- Existing customers: Are you growing your share of your customers’ wallets–especially those of your core customers? If not, examine what their existing and evolving needs are. Find out what new challenges are ahead and how you can help overcome them. Also find out who might be in a better position than you to meet those challenges–especially if their solution comes with a lower price tag.

- Acquisition of new customers: You can’t depend only on existing customers for a rise in revenue. You need an infusion of new customers who you can turn into core, long-term customers over time.

- Existing products: Do your products deliver the same or more value to your customers? If they’re not, what can you do to raise the value they offer and, in so doing, grow your customer base? You’ll need data-based evidence to make the right judgment call.

- New and temporary product sales: Market conditions change and so do the needs and priorities of your customers. Are you coming up with new ways to serve them? In what ways are your offerings keeping up with the changes?

- Customer defection: Is the customer experience up to snuff? How many customers do you have now compared to the same period last year? How many customers have fallen off your rolls? How many look like they’re about to jump ship? What improvements will keep them from switching to your competitors–without being a drain on your profits?

Final Thoughts

Market conditions have never been as uncertain and unpredictable as they are today. Keeping a lean supply chain will help any distributor get through difficult times, operating in new ways that prioritize liquidity over market share. This requires striking a balance–each one unique to each business–among profitability, customer experience, and revenue growth. Distributors must be able to simultaneously manage inventory, stratify customer bases, and implement growth strategies to maintain profitability.

This balancing act requires the right data and robust analysis to get it right. Because today’s marketplace leaves little room for error.